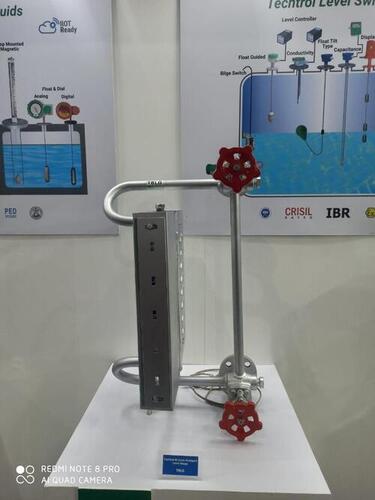

Port Level Gauge

Port Level Gauge Specification

- Thread

- BSP, NPT, Metric (as requested)

- Display

- Direct Glass Visual Display

- Glass Size

- Standard Size 20 mm width, length as per measuring range

- Sensor Type

- Visual Indication (Mechanical) Liquid Level Gauge

- Outer Size

- Dependent on model, standard 60 mm/80 mm (diameter)

- Case

- Stainless Steel / Aluminium / Brass

- Material

- Aluminium / Brass / Stainless Steel (304 or 316)

- Working Presssure

- Up to 10 bar (standard), higher on request

- Seal Material

- Neoprene, Viton, PTFE, Nitrile

- Grade

- Industrial Grade

- Application

- Other

- Mounting Orientation

- Vertical (standard), Horizontal (optional)

- Protection Class

- IP65 (standard, can be upgraded)

- Optional Features

- Magnetic indicators, Scale plate, Illuminator, Level Switches

- Glass Type

- Borosilicate/ Toughened for chemical resistance

- Maximum Temperature

- up to 120C (high temp designs available)

- End Connections

- Threaded / Flanged

- Connection Type

- Flanged / Screwed (as required)

- Color Options

- Indicator flags or balls for easy visibility

Port Level Gauge Trade Information

- Minimum Order Quantity

- 10 Pieces

- Main Domestic Market

- All India

About Port Level Gauge

YPL Bi-Color PortLevel Indicator is suitable for steam/waterapplication. It is high pressure boiler level indicator with multiport for continuous indication. Where presence of water is green indication is observed the illuminator viewing panel & red indicate Steam/Air.

| Fluid Type | Water |

| Material | Stainless Steel |

| Glass Material | Acrylic |

| Application | Refinery |

| Mounting Orientation | Top |

| Process Connection | Screwed |

| Type | Level Gauge |

FAQs of port level Gauge:

Q: How is the port level gauge installed and what mounting options are available?

A: The gauge can be mounted vertically as a standard option or horizontally upon request. Installation is straightforward, utilizing either flanged or screwed (threaded) connections compatible with BSP, NPT, or metric threads. This allows easy integration into existing or new tanks and vessels.Q: What materials and seal options are used to ensure chemical resistance and durability?

A: Our level gauges use borosilicate or toughened glass for excellent chemical resistance and high durability. Housings can be selected from stainless steel, aluminium, or brass. Sealing materials offered include neoprene, viton, PTFE, and nitrile, providing robust protection against a wide range of chemicals and process conditions.Q: When would I need upgrades like a magnetic indicator, scale plate, or illuminator?

A: Additional features such as magnetic indicators, scale plates, and illuminators are beneficial in conditions where enhanced reading visibility, accuracy, or remote level indication is required. These upgrades are ideal for low-light areas, critical safety applications, or when precise visual monitoring is essential.Q: Where can this level gauge be used and what types of applications are suitable?

A: This gauge is specifically designed for industrial tanks and vessels, making it ideal for oil storage, coolant tanks, hydraulic reservoirs, and a variety of process vessels. Its robust construction and high chemical resistance suit harsh processing environments prevalent in chemical plants, refineries, or manufacturing facilities.Q: What is the measuring range and accuracy of the gauge?

A: Measuring range is customizable according to application, typically from 100 mm to 350 mm. The device provides high precision with an accuracy of 2 mm, ensuring reliable readings for critical process monitoring.Q: How does the visual indication system work, and what are the benefits of magnetic indicator options?

A: This mechanical gauge provides direct visual level indication via glass, with optional indicator flags or balls for easy reading. Magnetic indicators offer the added benefit of remote level indication, reduced risk of leaks (since the process does not rely solely on glass), and clear visibility even from a distance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Gauge Category

Reflex Level Gauge

Price 6050 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Reflex Level Gauge

Usage : Pharmaceutical / Chemical Industry

Outer Size : 2.5 inch / 63 mm

Weight : 0.387 Kilograms (kg)

Transparent Level Gauge

Price 7500 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Transparent Level Gauge

Usage : Pharmaceutical / Chemical Industry

Outer Size : 2.5 inch / 63 mm

Weight : 0.387 Kilograms (kg)

Send Inquiry

Send Inquiry Call Me Free

Call Me Free